1

The Core Differences Between Cheap and High-Quality Vinyl Windows

One of the main objectives of every window replacement project is to achieve the highest energy efficiency by getting a high-quality window that is meant to last. Shopping for vinyl windows it’s very easy to get confused by so many available window products that claim to offer the best durable and efficient solution. We must keep homeowners informed on the differences between cheap and high-quality vinyl windows, especially if your budget is sensitive and expectations are high. The essential pillars of every high-quality window are multi-chamber frame, structural reinforcement of window profile, compression seal, hardware and handles. Let’s be more specific.

2

Cheap Window Hardware vs Quality Hardware

One of the most important parts of a window system, if not the most important part, is the hardware. The hardware, which is a system in itself, includes all the materials and non-metal parts that allow a window to open, close and stay in a properly sealed closed position. The quality of the hardware is also a key element for the performance of your windows but also for their durability and longevity.

Locking Points

What makes quality hardware is the design and the material used to manufacture them. Out there you can find windows with hardware systems that are poorly designed. There are a few things that you can check to make a quick assessment of the quality of the design.

Tie Bars

Some hardware systems have the lowest locking point above the locking handle. In fact, there are window systems that do not even have tie bars. A few companies are now offering hardware systems with tie bars also on the horizontal top part of the window.

Smoothness of Operation

Another easy way to recognize the quality of the hardware is by operating it. A smooth and secure movement of the system as well as a stable transition into the locked and unlocked positions are a clear indication of quality. The most sophisticated systems have also been designed to hide the gear mechanisms.

Materials

Another key element that makes a quality hardware system different from cheap is the material used along with the fabrication process. It is very common to see cheap hardware system made with folded metal sheets or metal stamped parts.

3

True Multi-Chamber Technology

To convince homeowners of buying a specific window, many window manufacturers claim to have windows with Multi-Chamber technology. It refers to a profile which observed through a cross-section and shows a lot of small pockets. Such a design was invented to improve the structural performance preventing warping and enhancing the sound insulation. Double or triple glazing is not the only component when it comes to high-quality window performance. If you want to achieve the highest efficiency values, next time discussing window performance features, let your sales representative inform you about their windows frame technology used.

4

Window Reinforcement for Structural Rigidity

As window systems are getting larger and larger, manufacturers have been forced to find ways to add reinforcement to the windows to avoid distortion, deflection and provide some sort of structural rigidity. Reinforcement can be placed in-between window units or inside the window itself; inside the sash (moving parts) or frames (the fixed part of the windows).

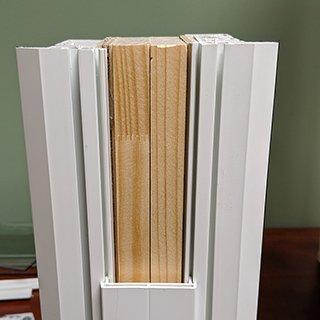

In-Between the Windows

Many manufacturers add wood profiles in between windows to reinforce their structure. If on one side this solution has avoided the substantial cost to redesign the window systems and keep utilizing old technology on the other, it cannot provide energy-efficient and proper joints between windows without adding two extra inches to hide a 2 x 4 wood profile.

Comparing a cheap window vs high-quality window, a good window system features profiles with a high degree of rigidity. This is achieved through a proper design engineering and using the right amount of material, look for the wall thickness of your window profiles. Those systems are already engineered to accommodate steel-based reinforcement for large applications without compromising performances or view of your windows.

Inside Window Profiles

As a window unit reaches certain sizes manufacturers add reinforcement inside the window to avoid distortion, deflection and provide some sort of structural rigidity. Some manufacturers have been inserting metal (in most cases aluminum or steel) inside the sash (moving parts) or frames (the fixed part of the windows).

The metal reinforcement inside the window, often “sold” as a benefit, is actually a symptom of limitations as it is needed to provide the structural rigidity to the window elements. In addition, metal elements conduct heat through the system compromising the overall performances of the window.A good window system features profiles with a high degree of rigidity. This is achieved through a proper design engineering and by using the right amount of material, look for the wall thickness of your window profiles. A good window system does not require metal reinforcement inside the profiles unless you are working on extreme large applications.

5

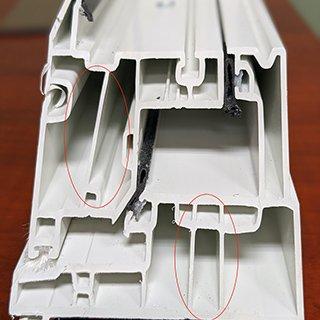

Compression Seal – Cheap Window Insulator vs High-Quality Insulator

Windows and doors main function is to isolate the inside of your home from the outside elements. You definitely want a window that keeps the water out, but you also want a window that is not drafty and protects you from the elements for many years. A high-quality operable window that can deliver that has a superior design, quality hardware and quality sealing element.

Sealing elements are placed between sashes and frames and can be in the form of a pile (weatherstrip) or bulb seal. Weather-strips are used mainly for sliding windows. You want a few of them between the sash and the frame. A very good window will feature three. Low-cost windows one or two. Bulb seals are used on Awning and Casement windows.

There are many systems where instead of bulb seals manufacturers use coextruded PVC black or white coloured gasket. This is a huge limitation for a good quality window and you really do not want that. PVC does not have memory and will lose the sealing power in a few years. Also is has a lower freezing point and breaks easily. Also being a part of the window frame, if it breaks it cannot be replaced leaving your entire window compromised. This is another core difference between the cheap and high-quality window.Make sure your windows have good seals!

6

High-Quality Window Handle vs Cheap quality

As you already know, the hardware is a key part of a window and the quality of the hardware in itself can determine the quality level of the entire window. When it comes to the there are two main things to keep into consideration; smooth operation and finish. Try operating the hardware and you will be able to tell by the sound it makes. There should not be any foreign noise. Listen to how smoothly it turns and how it transitions into the open and closed positions. In some cases you will find hardware that operates loosely, or is too stiff, does not stay in position or it makes difficult to operate. These are the signs of the low-quality hardware.